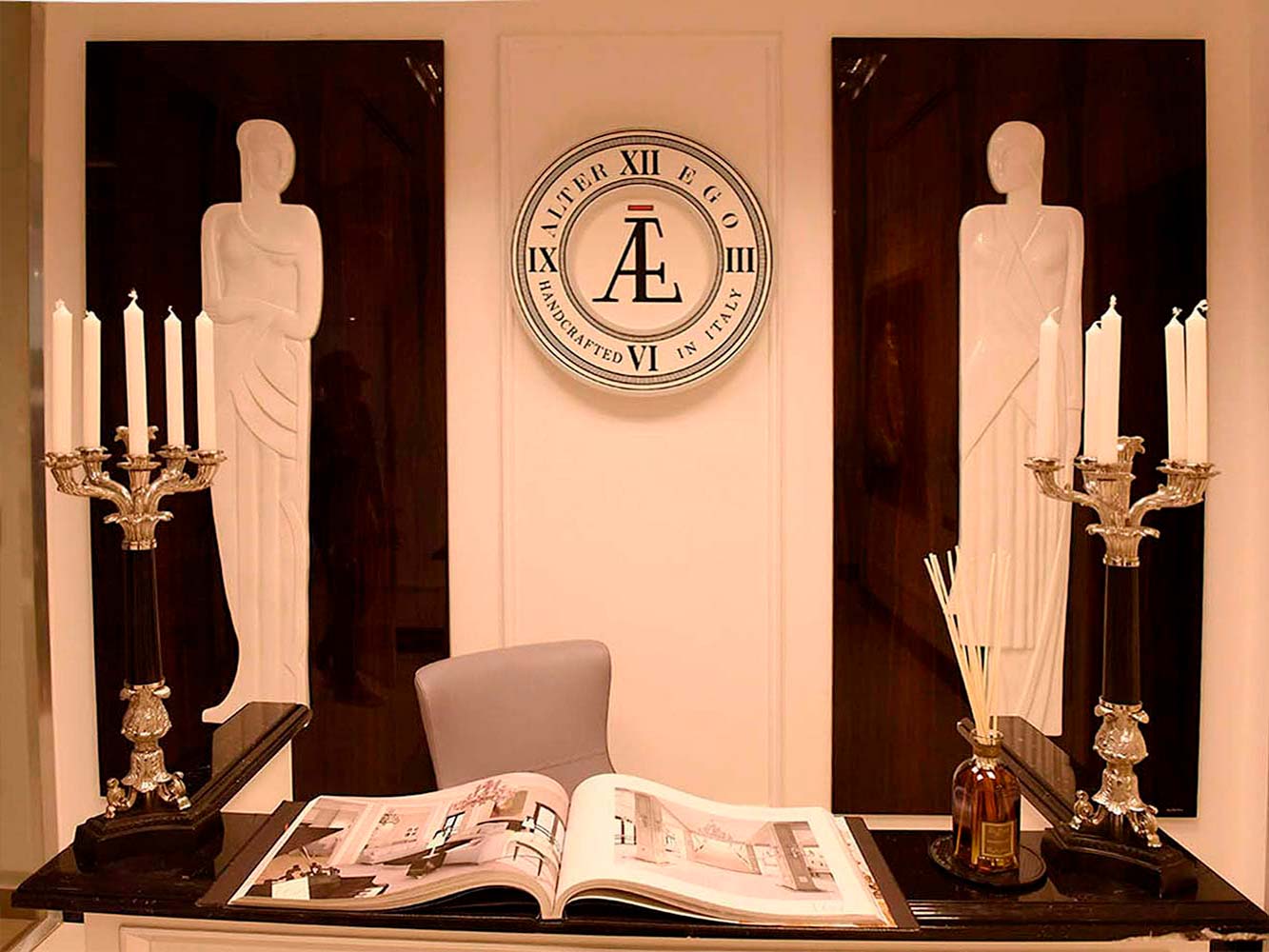

Expertise, reputation and connections are the foundation of business today. Who produces the highest quality furniture; where to find rare materials; and how to deliver goods on time and on budget? ALTER EGO holds the answers. Over 19 years, our team have gained the knowledge and experience for you, our Customer, to enjoy the best.

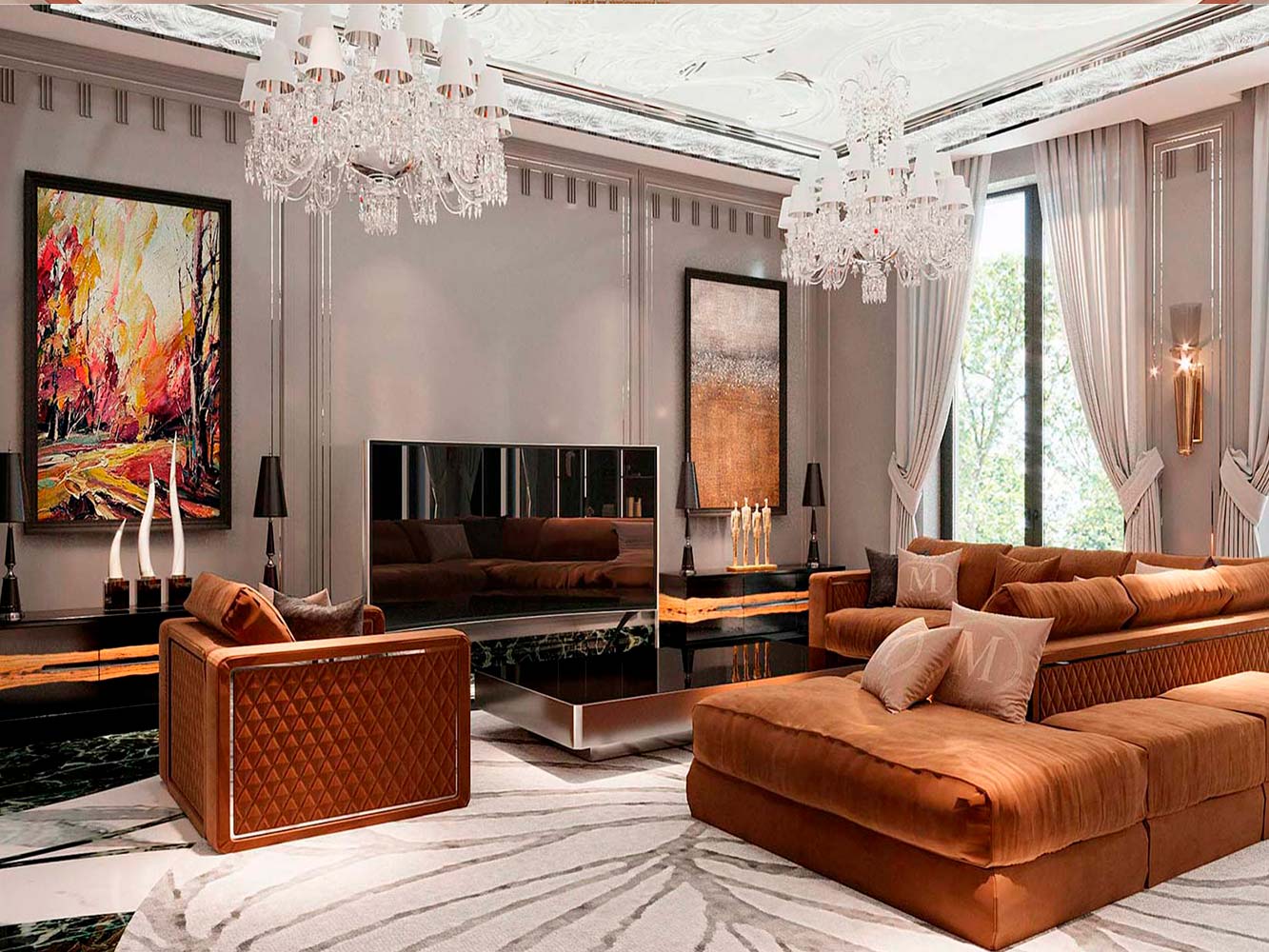

We work with leading manufacturers of the Old and New World - the best makers of luxury furniture, lighting, décor and finishings. ‘Fitting out’ is a flagship service for which we are globally renowned. In order to navigate a plethora of manufacturers and their standards, you demand expertise. It has taken time and diplomacy to earn our reputation as a dependable partner, able to access special items under unique terms. Our Customers value bespoke service, at a time when interior designers are inspired not only by contemporary trends but also by the technical achievements of individual manufacturers, the rarity of collector's pieces and the desire to obtain exclusive objects. A particular interior may demand unique marble direct from the quarry or a rare wood for veneers or custom-made furniture. Our team is there to control every stage, providing logistics and installation to an exacting schedule.

- Creating mood boards to bring interiors to life

- 3D-visualizations of custom-made items

- Finishing material specifications complete with imagery, full descriptions and costs

- Technical drawings for manufacturers

- Visiting quarries, suppliers and manufacturers to select natural stone, interior items and lighting

- Quality control throughout the production process

- Checking the quality of all goods and their packaging prior to dispatch

- Full control of the assembly and installation of all products ordered

- Complete trouble-shooting of any issues installing custom-made products

BOOK A MEETING

welcome@alterego-group.compartnership

partners@alterego-group.comPhone number and whats app

+ (39) 3920201195Phone number and whats app

+ (39) 3285824833BOOK A MEETING

welcome@alterego-group.compartnership

partners@alterego-group.comPhone number and whats app

+(39) 3920201195Phone number and whats app

+(39) 3285824833© 2024 ALTER EGO. All rights reserved

Privacy policy & Processing personal data

СТРАНЫ БАЛТИИ / Частное имение / 2 300 кв.м

СТРАНЫ ЛАТИНСКОЙ АМЕРИКИ / Частное имение / 42 400 кв.м

СТРАНЫ ЕВРОСОЮЗА / Частное имение / 102 500 кв.м

Thank you! We’ve already proceeded with your inquiry. Our manager will contact you shortly.